When the first version of the "Pendulum 2-stroke" was not found to be viable (click here for the page), I decided to rebuild this engine with a flywheel concept instead of a pendulum. In this way I could maintain a relatively large portion of the engine and it would still yield Pressure controlled 2-stroke Sabine. Hence I baptised this design the "2-stroke Sabina nice engine. In fact, it was a variant of the e MK2" which has the following differences with his predecessor:Introduction

- Simpler and more compact design;

- A glass cylinder containing a graphite piston;

- A double flywheel construction;

- Easy carburettor variant.

To be honest, the "pendulum 2-stroke" would have been more innovative and spectacular but you can force physics and the practice.

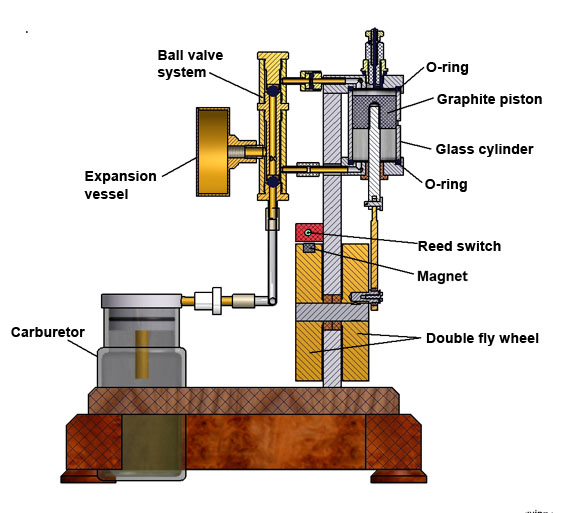

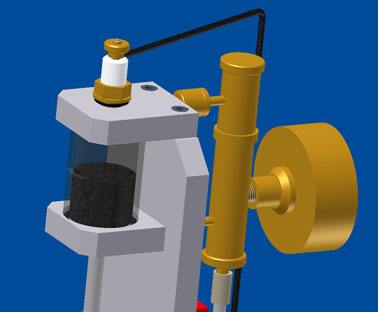

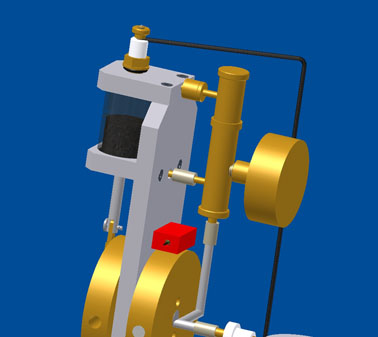

The designThe figures below illustrate the design:

The 2-stroke unit

In fact, I took over here the 2-cycle concept of "Pressure controlled 2-stroke Sabine" with the difference that here the cylinder is made of glass and the piston of graphite. A system with two ball valves and an expansion tank automatically takes care of the suction of the fresh gas mixture from the carburettor, the compression thereof, in the expansion tank and the flushing of the cylinder at the moment when the piston passes the exhaust opening in the cylinder in its lowest position . In contrast to the standard two-stroke process here the fresh gas is injected at the top of the cylinder instead of through an inlet opening in the wall of the cylinder.

As I with several of my IC engines I have here the glass cylinder cut from a 20ml 'Fortuna Optima "syringe whose inner diameter is extremely accurate with a roundness of 0.01 millimetre or less. This is a precondition to make a well-fitting graphite piston in it.

I myself obtained a few of these syringes from a fellow modeller so I have never bought myself such a syringe until now . But suppliers for this "Fortuna Optima" syringes are everywhere on the Internet; simply type "Fortuna Optima syringe" into Google Search (or "Fortuna Optima syringe"),see the picture below:

I

The prices are about 10Euro a piece for example at:

Sigma Aldrich

Art. 20ml Z314366-10EA

glass Luer style; 10.50 Euro

http://www.sigmaaldrich.com/technical-service-home/product-catalog.html6

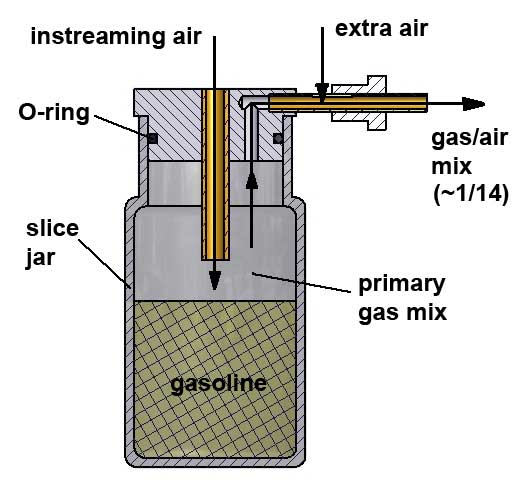

The carburettor.

The carburettor is a variant of the universal Petrol Vapour Carburetor with otherwise the same principle. This variant is a strong simplification where I used a small spice jar as gasoline tank. At the top side it is closed by a metal cover with the lead for the inlet of the outside air and the outlet with the controller for adding outside air; easier is hardly possible I think. This vertical version also fits better in the relatively compact design of the engine.

The flywheels.

I have applied here two coupled flywheels, one at the cylinder side of the vertical support with the eccentric for the connecting rod and one on the other side with a Neodymium magnet for controlling the reed switch for the spark-ignition. This also serves as a flywheel start-up pulley with two holes for a start-up tool in the hand drill.

The ball valve system.

Apart from some small dimension differences this system is identical to that of the "Pressure controlled 2-stroke Sabine".

Below an animation of this 2-stroke process:

The expansion vessel that can be seen on the cross section (not on the animation) is intended to limited the compression pressure under the piston. A too high pressure would brake the engine severely. This pressure need only be just enough to flush the cylinder well with the fresh gas mix at the time when the piston is in its lowest position and the outlet opening is opened.

The spark system

I used the spark system according to alternative 2 that you can find on the page: "Blokker spark circuit"

*****************************************************************

Unfortunately this gas lighter with this specific circuit is almost nowhere for sale any-more as far as I know. A good alternative is a ready-made small electronic spark system for model engines, for sale at AliExpress for about 16 Euro, search with:

aliexpress cdi spark igniter and then choose the circuit below:

It seems to mee a good idea to make a small extern unit with this circuit once, which can be connected then to any model combustion engine.

**************************************************************

Video:

Drawing Plans

I made CAD plans for this engine that are available for every one interested; click here for a request.

Horizontal version

made by Huib Visser: