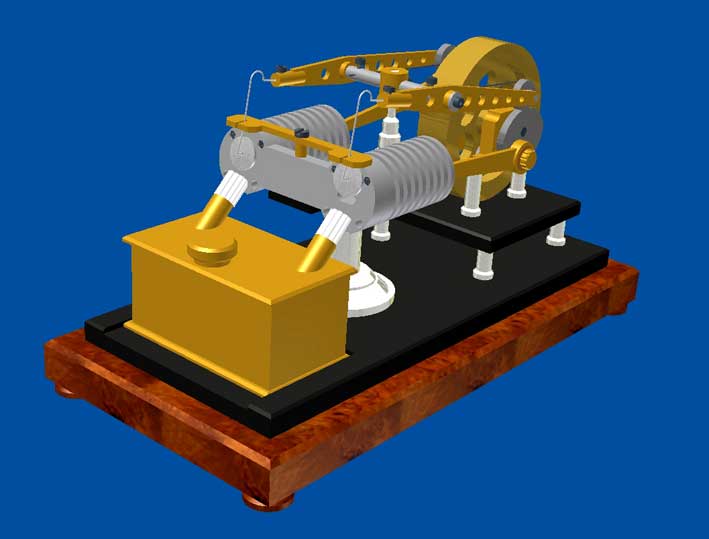

IntroductionAlready in 2004 I made the first version of this 2-cylinder flame-eater, click here for the page. This engine runs okay but only if the drive system for the two slide valves are made well and properly adjusted. But the design of this drive system was fairly complex and it was also quite difficult to adjust it properly. It is a critical element in that design where a lot of modellers stumbled about as far as I received confirmations.

After ten years, I took this flame-eater again out of the closet to try to simplify this drive system and thus drastically improve it at the same time. I made use of the experience I gained in a similar adaptation of the "Miniature Vlamhapper", click here for the page of that engine.

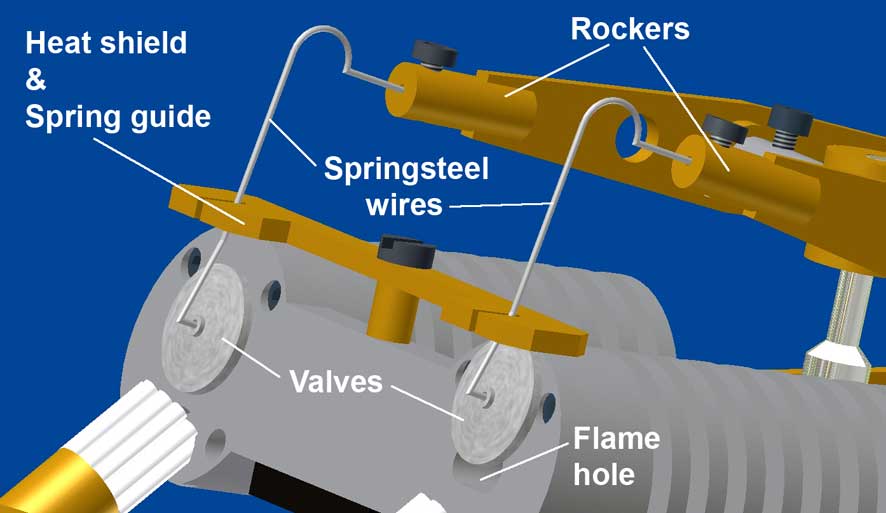

The improved valve system and its adjustments.The figures below illustrate the improved system:

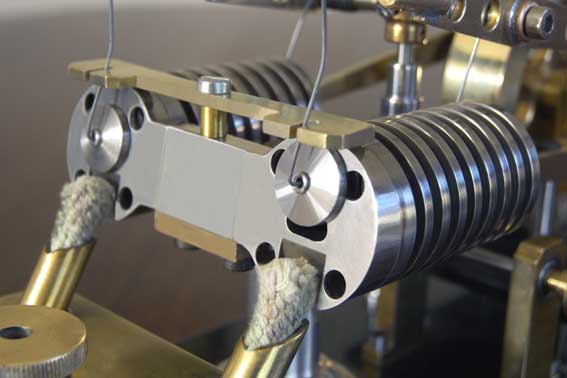

The original system with rectangular slide valves that were driven by the twin and double spring-loaded carriers is thus replaced by circular slide valves that moving up and down with the simple and single wire springs. A heat shield that also serves as a guide for the springs prevents the springs from losing their resilience due to annealing by the alcohol flames, something that it was a problem with the original design.

In fact the spring only must carry the valves with a pressure as low as possible against the cylinder head in order to make the friction low. The light spring force must only ensure that the valves remain pretty flat against the cylinder head while going up and down. This is a matter of making the springs with the right dimensions and bending them "on the spot" in the right shape.

This spring pressure itself is hardly or not important for the good sealing because that sealing is a result of the outside pressure that presses the valves against the cylinder head when the partial vacuum in the cylinder occurs while the cooling-down of the sucked-in flame gasses, provided the slides are flat positioned against the cylinder head during that process period.If the valves properly close the flame holes this escape of air through the sliding is audible with a "puffing" sound when the flywheel is rotated manually without flames. This sound is caused by the cold compression of the air in the cylinder pushing the valves somewhat away from the cylinder head against the light spring pressure; see also the demo part of the video right on top of the right frame of this page.

Due to the round shape of the valves I had to increase the stroke of the valves for which I had to change the cams that drive the rockers a little. If the valves are in their lowest position they must overlap the flame holes with about 1 mm for a good seal. If the valves are in their upper position the flame holes than will be opened for approximately 3/4.

It is advisable to first adjust the engine with only one piston/cylinder assembly with all the above considerations and let it run. This because it can be that one half of the engine is properly tuned but not the other half and then the engine mostly is not running because the good half must take the ballast from the other half which does not work. So at this single tuning disassemble the other piston including his rocket tumbler with valve. The engine will also run very well with only one piston provided you remove the ballast from the other half.

If the engine with one half is properly adjusted and running the same procedure must be carried out with the other half with the other side disassembled. If the engine also runs with that half assemble both parts and this flame-eater will frantically run away.

The result of this improved valve driving system.

Except that this valve drive system is significantly simpler to make is also has the advantage that the adjustment thereof also became considerably simpler and uniform. This means that the engine is much more reliable than its predecessor and readjusting over and over again of the the valve system now is redundant.Video:

">The engine runs with a speed of about 1000 rpm when the water condense from the flames in the cylinder has disappeared after about one minute. This water condensation occurs at startup for every flame-eater, preventing well running during the first minute.

It is recommended to use alcohol 94 to 96 % instead of domestic spirits because the alcohol flame is hotter and causes less pollution of the piston and the cylinder bore than domestic spirits; this applies to all flame-eaters by the way.

Drawing package .

For this 2-cylinder MK2 version I have made a new CAD drawing package which is available for anyone interested; click here for a request.

Beautiful replica Steve Johnson:

Beauitiful replica made by

Cristobal Jaramillo:

Wonderful replica by

Antonio Fattore :

Nice replica made by

Gerard Versluys: