Introduction

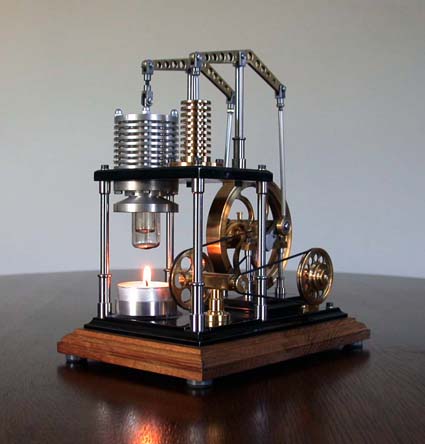

Already in 2003 I have derived this design from a photograph on the web site of the commercial Firm " Wiggers" in Germany , with some single data concerning the diameter and stroke of the displacer and work piston. In the original engine Wiggers design a spirits burner is used for the heating of the glass hot cylinder. I have adapted this design on a number of aspects, among others to let it run with a small flame of a waxine tea light. I consider this kind of model motors more or less as technical "ornaments", who need to show their skills in a living room setting. And in that environment a spirits burner is not quite recommendable, mainly because of the easy spilling alcohol with a risk of fire on the table. Waxine tea lights don't have this objection and burn moreover for hours burning without spreading any unpleasant smells. This candle light flame does provide a somewhat lower power than the hotter spirits flame, so I had to o take a number of measures to compensate for that. So I applied ball bearings on the flywheel crank shaft and on the driving rods between the crank shaft and the rocking arms. I have also paid special attention to the correct alignment of all rotating parts and I add an aluminium flame shield over the hot cylinder to increase and maintain the temperature difference between the hot and the cold zone of the engine.

Furthermore I also added a little transmission system with rubber belts and with a double delay. Thus it has become possible to drive some small external device which incidentally I did not do that yet.

Some technical details and used materials.

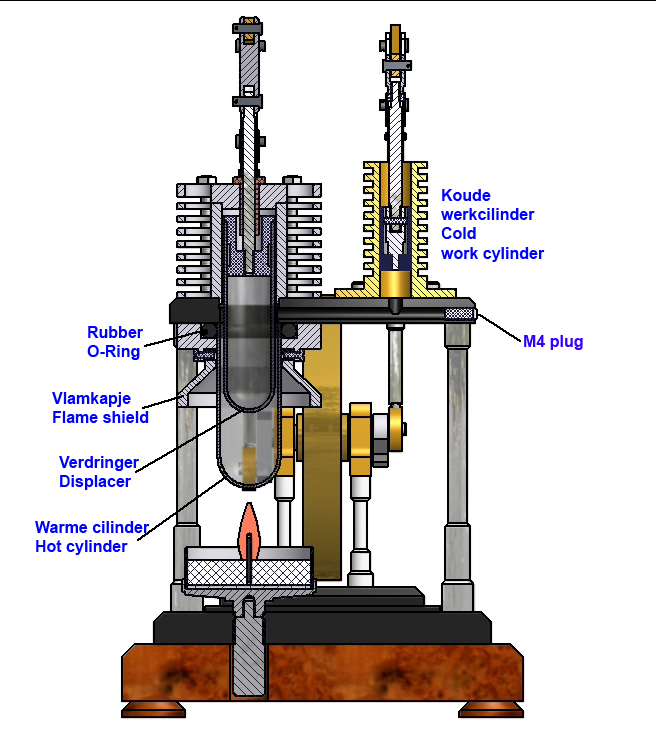

The hot cylinder and the displacer therein are cut from heat resistant Pyrex test tubes. These tubes must fit into each other with a clearance of 0.5 to 1 mm to allow the air in the system passing form the hot to the cold cylinder and vice versa every cycle. The glass hot cylinder is clamped in a pressure piece on the bottom of the mounting plate with a rather thick rubber O-ring, so that it is fixed, both mechanically and airtight. The glass displacer is inserted with a little silicone sealant over an aluminium mandrel, to which the connecting rod is attached.

I have made the aluminium cylinder at the top of the mounting plate out of one piece with cooling fins. This is in contrast to the model Wiggers, where this component consists of a series of stacked square plates which in my opinion is difficult to make this cylinder really airtight.

The brass working cylinder with cooling fins is also made from one piece. The hole for the working piston is drilled in a number of steps to a final diameter of about 9.9mm. Thereafter this hole is made nicely cylindrical and smooth with a sharp 10 mm reamer. The working piston is of chromium steel and has such a 10mm diameter that this piston fits somewhat "sticky" in its cylinder. Then the piston is polished manually in the cylinder with a fine polishing compound till it runs nicely with low friction and almost air-tight in the cylinder. If one close off the cylinder with the thumb the piston must keep hanging in the cylinder; when the the thumb is drawn away the piston must immediately fall down by its own weight. It is absolutely not advisable to lubricate here with any oil whatsoever! It is my experience that this engine than runs bad or not at all due to the viscous behavior of the oil, the thin it is!

The holder for the tea candle is standing on a threaded spindle which is adjustable in height with approximately 10 mm.

The two mounting plates are made of aluminium which I lacquered black after all operations.

The two cylinders are mounted on the upper mounting plate with a thin film of silicone sealant in order to make an air tight connection. The hot and the cold cylinders are atmospherically connected to each other by a 3.5 mm bore. This hole must be plugged airtight with an M4 bolt.

Some dimensions and engine performance

Outlines: L*W*H = 180*110*190 mm;

Work diameter piston 10mm, 20mm stroke;

Diameter hot glass cylinder: outer 20mm; inner 18mm;

Diameter glass displacer: outer 16mm; inner 14mm; stroke 20mm;

Brass flywheel diameter: 100mm; width 12 mm.

Well adjusted this engine runs with about 800 rpm, depending on the height adjustment of the tea light candle and the size of the flame.

CAD plans

I made this Stirling already in 2003 and, as stated before, on the basis of the design of the Firm Wiggers in Germany. I have applied a number of changes as described in the introduction section at the top of this page. Because the original design was owned by Wiggers I did not make a CAD drawing package before for making that freely available to every model colleague. But the firm Wiggers shortly has stopped their modelling activities and I have therefore asked them whether they allow me to make a drawing package of my version and to make that available to everyone interested. They have responded positively so that I now (May 2016) have made a complete CAD drawing package for this Stirling model; click here to make a request.

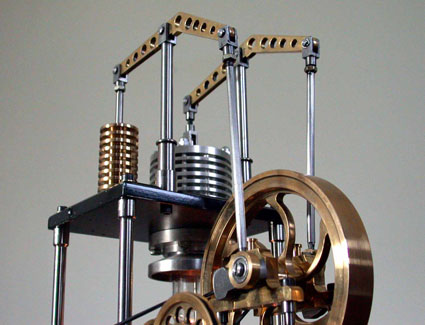

Very nice replica made by

Antonio Fattore: