The Idea

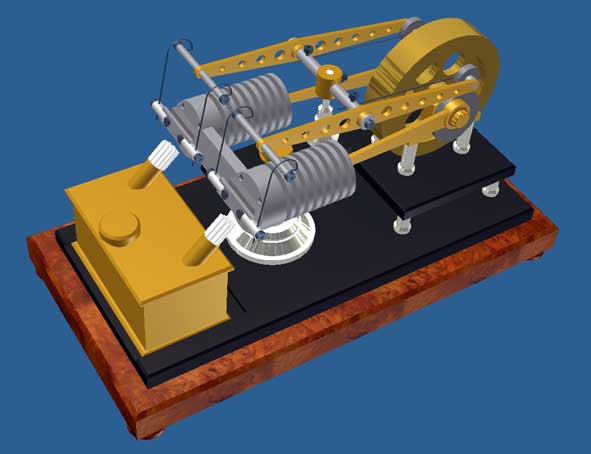

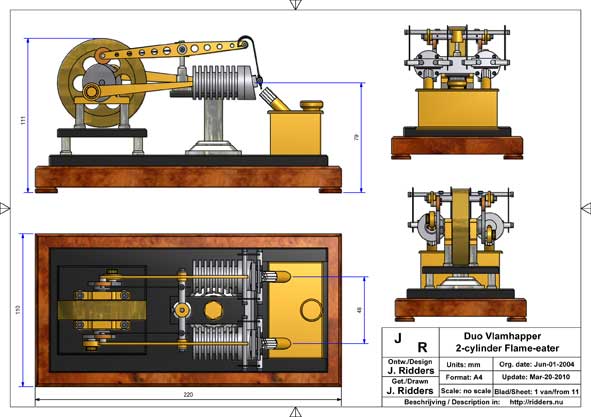

In fact this was my first flame-eater and totally according to own design. So I build this engine earlier then the vertical 1-cylinder Vlamhapper Marc. But my knowledge about flame-eaters at that moment was far below the level needed to get flame-eaters to run. Several times I reached the point dumping this engine in my litter bin, until I decided to build the vertical 1-cylinder first according to an existing drawing plan. So, certainly this engine should run and I hoped to learn so much from this that I got the keys in my hand to let this 2-cylinder run. And that appeared to be the case, although not without a lot of experiments and patience. But the persister often wins at the end and all the efforts came out to be worthwhile because I consider this engine as one of my favorites !Sheet 1 from drawing plan

Technical data

The cylinders with cooling vanes are made out of rust free steel. The cylinder bores are 12 mm diameter and the stroke of the pistons is 20mm. The total cylinder volume is about 3 times smaller that that of the vertical 1-cylinder: 5.3cc versus 15.2cc. But this 2-cylinder runs much more smoothly and quiet than the 1-cylinder and with higher speed. The reason is that the pistons are 180º out of phase with the result that when one piston is powerless while sucking-in the flame the other is in the power phase and vise versa. So with this 2-cylinder there is no real dead stroke in the cycle which is the case with the 1-cylinder during half the fly wheel cycle.

The cylinder bores are made exactly cylindrical and smooth by hand reeming with an adjustable reamer for 13mm using redundant oil. The trick is to turn around the cylinder several times with the same reamer adjustment and repeat this treatment with a fraction wider adjustment of the reamer until you cannot measure any diameter difference anymore.

The pistons are made from pearlitic cast iron with such a diameter that they move somewhat "sticky" in their cylinder. The last few microns are removed by hand greasing with a fine greasing paste.

It is very important that the pistons move very easily in their cylinders but with the smallest possible air leak at the same time. Test as follows: while closing the cylinder bore with your thumb the piston must keep in place in the cylinder; immediately after removing your thumb the piston must fall through the cylinder by its own weight. This test must be done without any oil in the cylinder.

The two pistons are driven by their respective eccentrics which are made such that they are cam discs at the same time for the tumblers to drive the slide valves over the flame intake holes in the cylinder head plate. These eccentrics are mounted 180º shifted on the fly wheel axis.

Each cam disc has a radial slotted hole in which the little axis for the driving rods can be fixed. The slots make it possible to adjust the positions of the pistons in relation to the position of their glide valves in such a way that the engine will run optimal. This fine adjustment is very important to let the engine run smooth and reliable!

Each tumbler has a torque spring to ensure that the roller always keep contact with the cam disc. The strength of these springs must be just enough to avoid that that the tumblers start floating. I made this springs from 0.5mm spring steel wire.

The spirits flames are burning on two wicks in one tank. For all flame-eaters counts that the position and the size of the flame in front of the hole in the cylinder head is very critical ! Therefore it is advisable to make the tank somewhat adjustable in the horizontal plane to allow finding the best position in front of the cylinder head. Furthermore the height and width of the flames must be such that the cylinder holes are ample overlapped to avoid that outside and cold air is sucked-in together with the flame gasses. With the smallest amount of false air the engine will run bad or not at all !

Again it is my experience that no oil greasing must be applied in the cylinder. Oil will degenerate immediately due to the high temperature of the flame gasses which causes moisture on the surfaces that fataly slows down the engine. That's the reason why I use pearlitic cast iron for the pistons. This material is more or less self-greasing due to the high carbon content. But it is always necessary to clean the cylinders and the pistons between running the engine and storing it for some longer time. After cooling down some residues of flame gasses with water condense will stick on the surfaces of the cylinder and the piston that causes starting-up problems the next time. The construction is such that the pistons can be removed (and replaced) easiliy for cleaning-up with a cloth and some solvent like WD40.

Using pure ethanol instead of spirits will improve the engine's performance noticeable because of the hotter flame and it will decrease the pollution of cylinder and piston considerable too.

Engine Performance

The unloaded engine runs very fast with revolution speeds up to 1000 rpm or even more. The power of this little engine may be rather low, but I am convinced that it can drive something by decelerating the engine's high speed with a factor 50 to 100 or so. On the picture you can see that I add a transmission axis for this purpose. But I did not make up my mind yet what it should drive with it. But I have the time to think about it.

!! Look what Huib Visser made

of this !!

And this wonderful replica from

!!Lorenzo Porro!!