Global construction

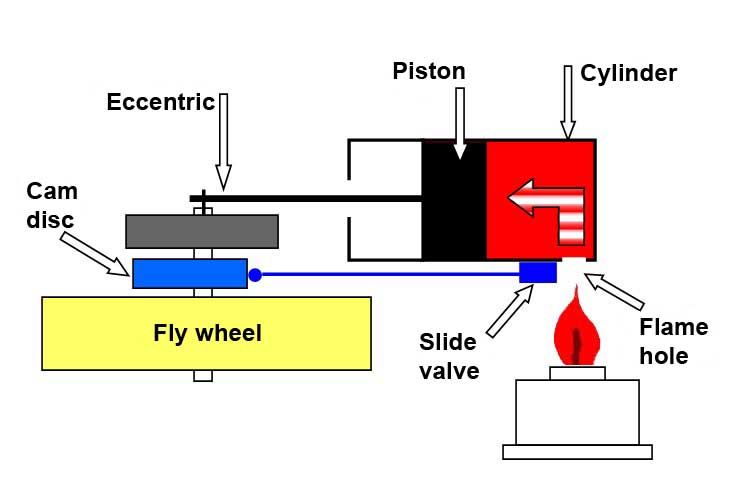

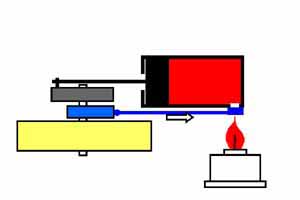

See also the schematic diagrams on the right of this text.

On a very light beared shaft there is a flywheel, a cam disc and an eccentric. The eccentric drives a piston by means of a connecting rod in a cylinder which is provided externally with cooling fins. The cam disc drives a spring loaded connecting rod with a metal slide on that, resulting in a special back and forth movement over a flame hole in the cylinder head. In front of this hole there is a flame of an alcohol burner.

This kind of engines are also named "Fire-Eaters" or "Vacuum Enfgines".

Global process

The hot flame gases are sucked in the cylinder as the piston moves away from the flame hole in the cylinder that is opened by the slide valve. If the piston is arrived to the left the slude valve closes the flame hole. The hot gasses thereby are locked up and cool down against the relatively cold wall of the cylinder, creating a partial vacuum in the cylinder. The outside atmospheric pressure drives the piston back in the reverse direction. During this stroke to the right the engine power is produced. The fly wheel effect ensures that the process cycle repeats itself.

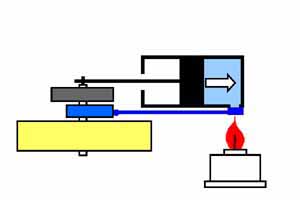

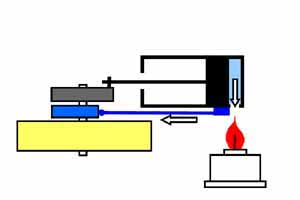

This process is actually very simple and visualised with the animation above and four positions of the piston and the slide in the 360 ° cycle on the right of this page.

Engine Performance

Because the partial vacuum created at a particular moment in the cylinder is only a limited portion of one atmosphere, the power of this type of motors is relatively low. Frictions and other counter-acting forces therefore must be limited to a minimum. The engine can run with decent speeds up to about 1000 RPM, but flame-eaters can hardy drive anything more than their own mechanism.

Adjustments

The choice of the materials used, the dimensions and in particular the setting of the various parameters of these flame eaters are found to be very critical! It requires a systematic approach and a lot of patience to achieve the optimal settings, but it is certainly possible and once adjusted properly they run reliably with a "satisfying simmer".

See also: "Experiences and Tips with Flame Eaters".

Flame Eater with Internal Valve

An own designed model with an internal valve is considerably less critical and its construction is extremely simple: see the animation below and click here for the concerning page.

This movement is caused by the flywheel effect. The slide valve is stationary in the left position during this movement of the piston, so the hot flame gases are drawn in the cylinder through the flame hole.

Even before the piston is at the left position (20 to 30 º earlier) the slide has closed the flame hole in the cylinder. The now enclosed flame gases cool-down by the heat dissipation to the relatively cold wall of the cylinder, which is provided externally with cooling fins.

The slide valve is stationary in the right-hand (closing) position during this movement. Due to the cooling of the flame gases there is a partial vacuum in the cylinder that enables the outside air pressure to drive the piston to the right. In fact this results in the engine power.

About 40 º before this position the slide valve opens the flame hole in the cylinder again, so that the cooled flame gases are driven to the outside. The flywheel keeps the movement going and the process cycle is thus repeated.