The Idea

I made this Flame-eater in 2003 as a birthday present for my son Marc. He likes this more forceful and noisy engines, rather than the much sweeter and tight-lipped Stirling models.

Design data

See for the flame eater principle the concerning page on this web siteI based this engine on a design from H.P. Ham, but I made some changes on that. Most important change concerns the cam disc that determined the motion of the valve over the flame hole in the top of the cylinder. In the original plan the valve opens the hole for only 90º which is far too short to let the engine run. Colleague model builder C. Goverde told me that the hole must be open for at least 160º and my experiments confirmed that.

If we define the top position of the piston to be at 0º in the 360º cycle the process schedule must be as follows:

0º: flame hole is completely open;

110º: valve is beginning to close the flame hole;

290º: valve starts opening the flame hole again.

So the flame hole must be closed already 70º before the piston reaches its lowest position and must be opened again about 70º before the piston reaches its top position. During this last 70º the cooled down gasses escape though the hole in the cylinder.

See also sheet 9 of the drwawing plan for the right adjustments and proces timing.Other changes were a double sided ball bearing of the fly wheel and the spirits burner construction, apart from some other and more cosmetic details.

I made the first hand made plan in 2003.

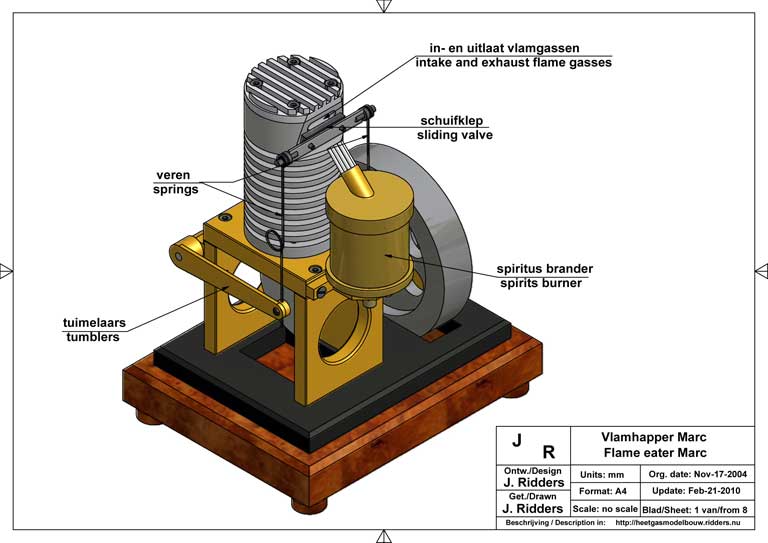

After I learned to draw with CAD I made a new and much better drawing plan in February 2010. At that occasion I implemented some minor improvements also. Below sheet 1 of this new plan.

Some technical details and used materials

The cylinder with cooling fins is made out of one piece rust free chromium steel. I drilled and lathed the cylinder bore to a final diameter 23.9mm and then reamed this bore with a sharp 24mm reamer. The piston is made from pearlitic grey cast iron (European code GG25). This is ideal material for this application because the thermal expansion is lower than that from the cylinder steel and it is somewhat self lubricating due to the high carbon content. The result is that no jamming occurs when the cylinder/piston combination gets hot. I made the piston diameter so that it fits somewhat sticky in the cylinder and then polished the piston manually in the cylinder with some fine polishing paste until the piston moves nicely in the cylinder with low friction and very small clearance.

Don't grease with oil because the hot flame gasses will make burned and sticky oil residues causing to high frictions. You can eventually spray some little WD40 through the cylinder hole from time to time if necessary.

Adjustment of the valve

Flame eaters have rather low power due to the small partial vacuum of the cooled down flame gasses in the cylinder. So too high frictions must be avoided. The two springs that drive the valve and also keep it against the cylinder surface must be bend and formed such that the friction is low and that the valve pressure at the cylinder is as low as possible. But the valve must have a constant contact with the cylinder surface. It is a matter of trial and error to bend the springs until this is realized.

The vertical adjustment of the valve can be done by fixing the springs in the desired position in the tumblers. The overlap valve/hole at the highest position of the valve must be small (between 0 and 1 mm).

Another critical thing is the size and position of the spirits flame. This must be so that only hot flame gasses are sucked in and no false and cold outside air is mixed with that. That's why the flame must be relative wide and high with a rather big overlap to the cylinder hole. Here again it is a matter of trial and error to find the optimum size and position of the flame.

Engine performance

Well adjusted the engine will run perfectly with a speed between 400 and 600 RPM. A good alternative for spirits is denaturized alcohol that contains 96 to 98% ethanol. The flame temperature is significant higher than that of spirits and it causes a much less pollution in the cylinder than spirits.Drawing plan

I made a CAD drawing plan for this Flame Eater Marc that is available for every one interested; click here for a request.

Beautiful version Huib Visser:

Ricardo Giordano:

Students ROC Amsterdam:

Nice replica by Chris Crocker:

Nice slow motion video

made by Peter Bengtsson:

Beautiful replica by

Cristobal Jaramillo:

Very nice replica by:

Chrix Build: